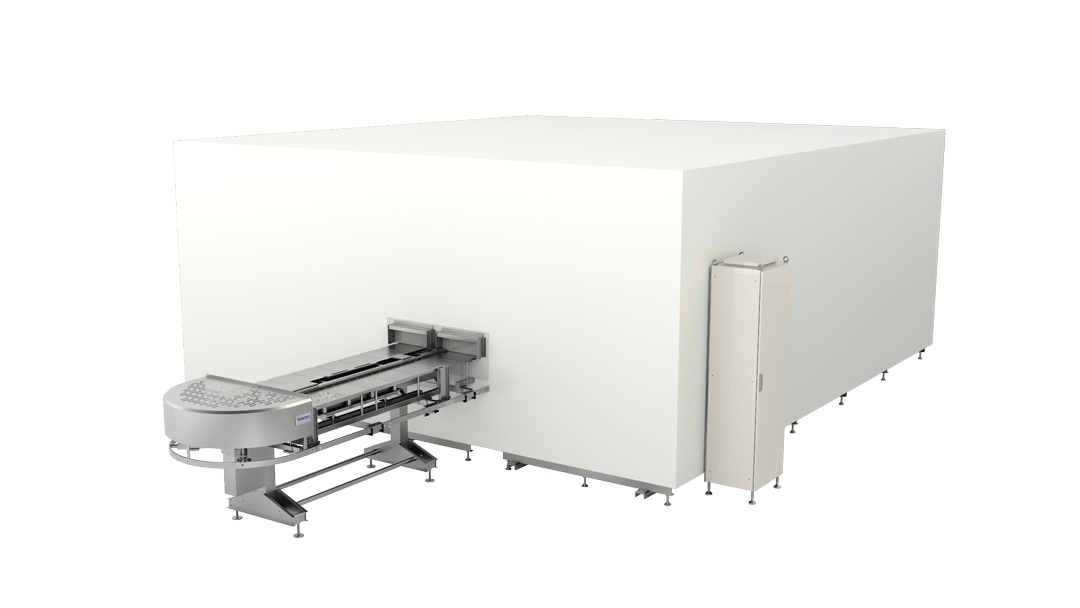

HT Hardening tunnels for the ice cream industry

HT tunnels are designed to rapidly harden cones, cups, family packs, cakes and more with a small investment of time and space, in relation to productivity.

Hardening tunnels are composed of an isothermal box, internal double spiral with adjustable mechanical movement, one or more evaporators, a set of trays with edges and a working table, with both entrance and exit of products at the front side.

HT tunnels can harden up to 2500kg/h of ice cream, reaching a maximum of -18°C, depending on the ice cream and its packaging characteristics.

On the inside, all the guides for the trays and evaporators are positioned to help air circulation. The dimensions of the evaporators and number of fans is determined by the requested productivity, temperature, ice cream characteristics and available space.

This rapid hardening process enhances the final structure and quality of the ice cream, highly reducing the time needed to deep freeze the products in the stocking cell. Enabling you to have stock ready for distribution in less time.

On request, Teknoice can also provide an automated pick-up system to load and discharge products from the trays.

Teknoice offers three different refrigeration solutions: Freon, CO2 and Ammonia.