Subscribe to our newsletter

Keep updated with our latest innovations.

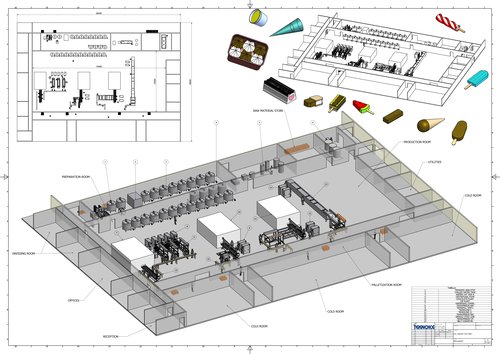

Whipping Up Efficiency: Creating the Perfect Ice Cream Factory Layout

- 20/11/2023

- Posted by: Debora Bolis

- Category: BLOG

An intelligent factory design can turn good products into a great business in the ice cream-making industry! Learn how to design a factory layout in the ice cream industry that can streamline workflows, optimize space management, organize machinery, and ensure seamless logistics for optimal production that boosts your revenues.

What are the key “ingredients” needed to design a sweet ice cream factory layout?

To maximize your ice cream business, discover how to design a factory layout in the ice cream industry for excellent results.

Think about your Ice Creams

The first element to consider when approaching how to design a factory layout in the ice cream industry is the variety of products to be produced—be it sticks, cones, or cups. While you know what products to make, each product has its peculiar needs, from creamy classics to fruity sorbets. For example, milk-based ice creams call for smooth pasteurizers, while sorbets look for a quick freeze with high-capacity coolers.

The industrial ice cream process can vary significantly in terms of ingredients, texture, and methodology. This requires a flexible setup that allows you to swiftly switch between products and production requirements. Factories that offer a variety of ice cream products can benefit from implementing separate production lines or have adaptable configurations that can efficiently accommodate fluctuating production needs.

Production Volume: The Making of a Mountain of Ice Cream

A well-designed ice cream factory layout is the backbone of success, supporting volume production goals, determining how many ice cream pieces per hour you can prepare and, thus, sell.. To keep up the pace with demand, your factory must be ready to adapt to ever-changing needs.

A modular approach is the key—it’s about scalability . An ice cream factory layout that grows and embraces changes and future opportunities can offer endless possibilities. This is why learning how to design a factory layout in the ice cream industry is vital.

An additional tip for even better results is adding in some high-tech robotics that can further boost efficiency. With such an approach, you can have production lines that not only keep up with the high demand but also set the pace for tomorrow’s ice cream bonanza!

Smart Workflow

Now that you know two of the main ingredients for a great ice cream factory layout, it is time to explore a third one that is just as important: a well-designed workflow. Your factory’s workflow will be critical to overall production efficiency, especially in the dynamic world of ice cream manufacturing. It is easy to imagine the benefits of streamlining the production flow to avoid unnecessary costs and inefficiencies. For example, positioning the wrapping section distant from the cold storage room or keeping raw materials far from the pasteurization area can cause immediate problems. Think of it as adding too much sugar to your gelato mix – it does not work well.

Therefore, your ice cream factory layout should be organized, with each machine playing its part in a logical sequence. This ensures smooth transitions from one stage to the next, minimizing movement and maximizing productivity. The typical production line might look like this: Raw materials start in the preparation room, where they are transformed and then sent to the production room. When ready, the products are moved to palletizing, followed by a pre-storage room stop before finally entering the storage room awaiting delivery. Efficiency and quality, from start to finish, and your business is ready to enjoy success as much as your customers can enjoy their ice cream.

Teknoice: efficient machinery and layout support

Teknoice, with extensive experience in industrial ice cream production,, offers a wide range of machinery that includes pasteurizers, freezers, extrusion lines, variegating pumps, and fruit dispensers. However, the Company’s expertise does not end at manufacturing.

Teknoice also plays a pivotal role in designing ice cream factory layouts, from the initial sketch, considering room dimensions and client needs.

Our guidance spans from machine placement strategies to avoiding hidden costs, like the time spent moving raw materials or retrieving finished products. Furthermore, since each company’s needs are unique, we provide customized machinery and suggestions, ensuring that your ice cream factory layout perfectly aligns with your operational objectives. Contact Teknoice to gain more insights and support in your ice cream machinery selection and ice cream factory layout optimization!