Pasteurizing and homogenizing are the first steps in making ice cream for both industrial and artisanal producers. It enables the ingredients to be thoroughly mixed and break down all particles to their smallest possible size resulting in creamy and smooth final texture.

Perfecting the ice cream recipe is also important but the common challenge can be finding the right balance between preparing ingredients at the right temperature.

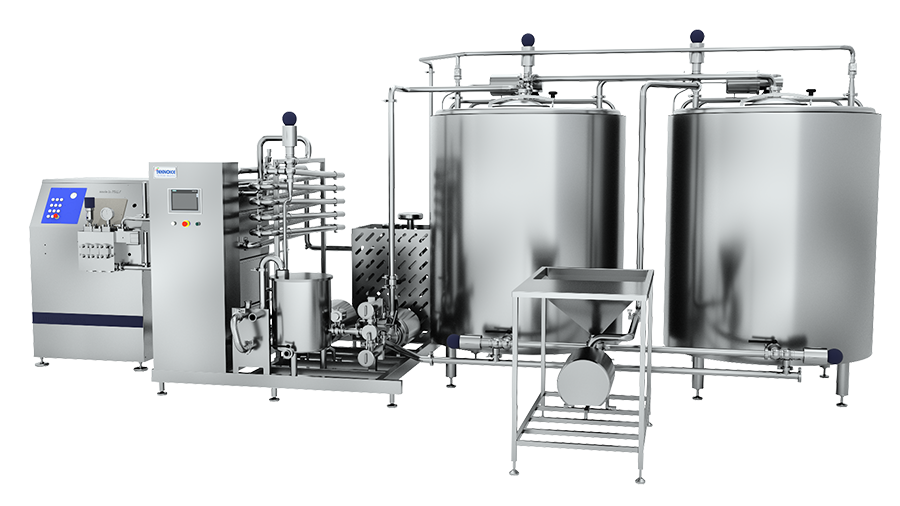

All Teknomix lines are user-friendly, easy to clean and require little maintenance, saving costs and time.

TEKNOMIX BATCH vs TEKNOMIX HTST pasteurizing plants

Batch and HTST pasteurizing plants differ not only in footprints and productivity, but also how the mix is processed before arriving to the aging tanks.

Teknomix BATCH is the ideal solution for small and medium ice cream producers while HTST is normally intended for medium to large ice cream manufacturers, where energy saving is crucial.

Overall, the process is similar: all ingredients are mixed, pasteurized (heated), homogenized and cooled. The mix is then aged before being churned by freezers.

Teknoice equipment can achieve the best results thanks to constant attention paid to all production steps and the quality of parts and materials used. Teknoice equipment is not only built to Italian or European standards but to satisfy customers all over the globe.